Page 1 of 1

Definitely headgasket?

Posted: Fri May 09, 2014 10:15 pm

by neil_1821

So all the symptoms were there that my head gasket had gone on the 400 even though the previous owner had rebuilt it and done zero miles on the engine.

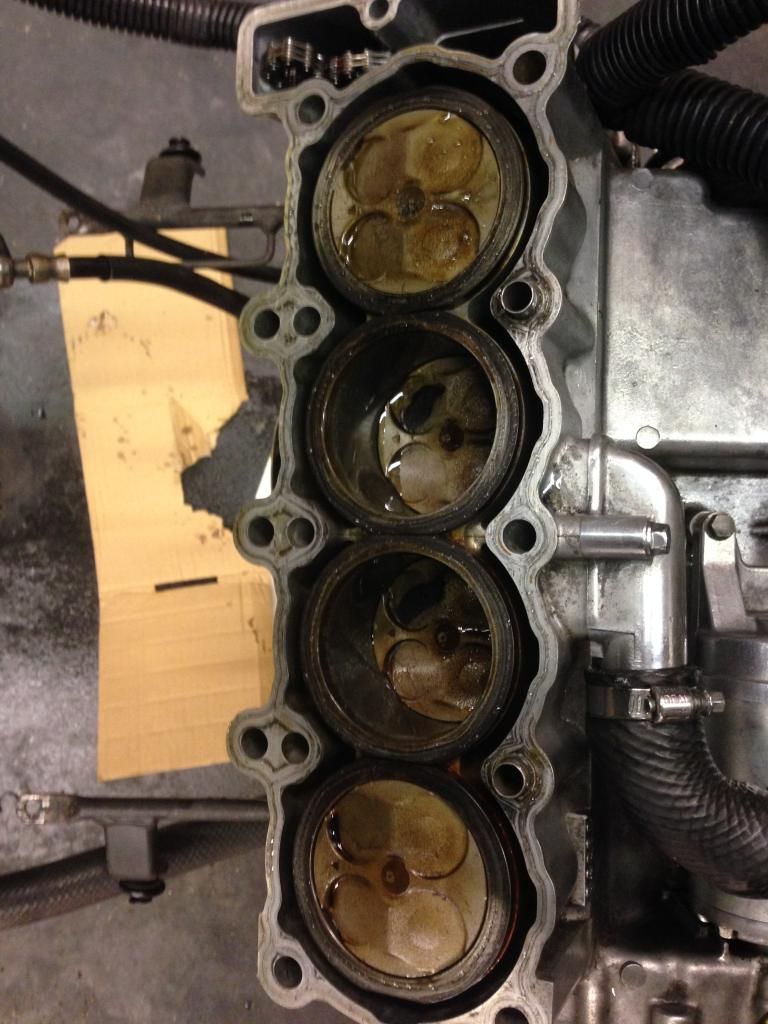

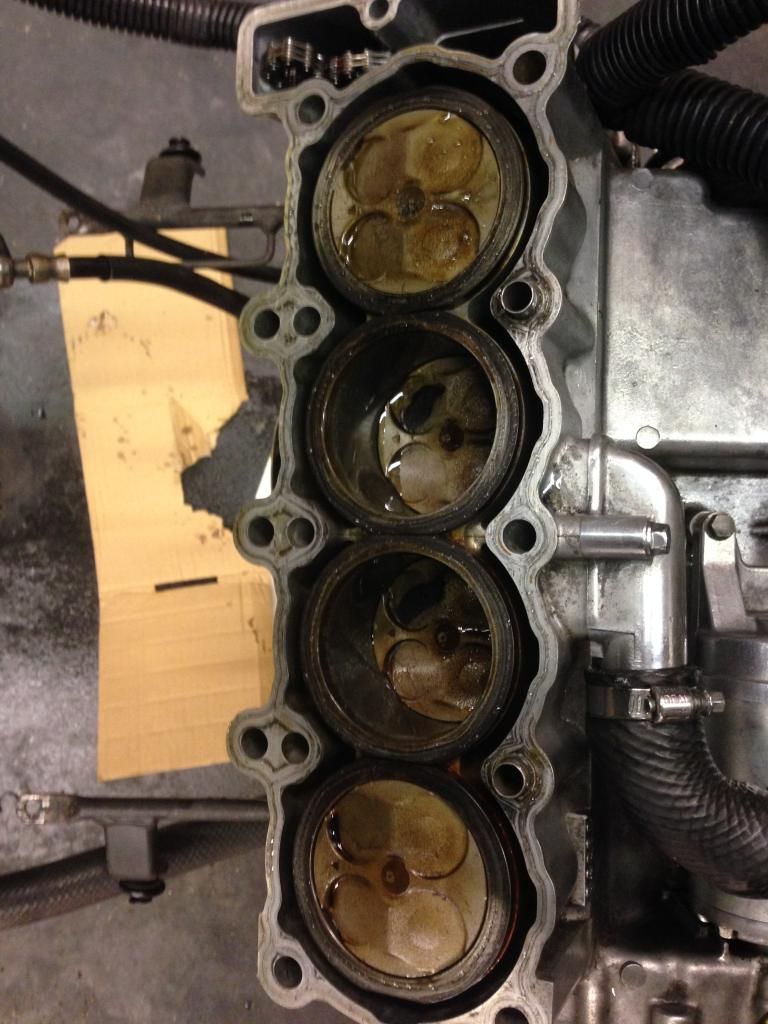

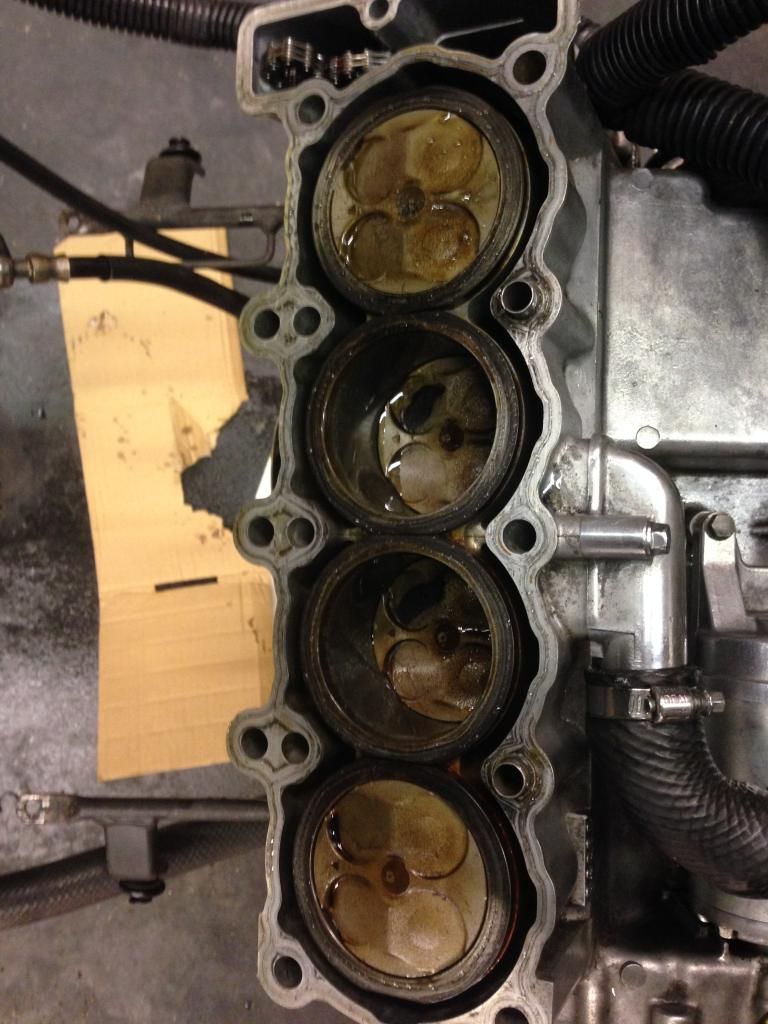

I was getting white smoke out the exhaust when trying to start it, coolant system was over pressurising, creamy white on the oil glass and oil filler cap and oil level had risen.

I've stripped the head off today and the cylinders did have some water in, although I can't see that the headgasket has definitely failed. The only signs I can see is where the black has come off and is exposing the silver but is that proof enough that it is the headgasket?

Re: Definitely headgasket?

Posted: Fri May 09, 2014 11:11 pm

by kawazonkey

You can never be 100% sure the head gasket has gone on anything...could be a cracked block or any number of issues. Since you've gone this far I'd suggest doing the head gasket anyway and see what happens.

Re: Definitely headgasket?

Posted: Fri May 09, 2014 11:21 pm

by CaNsA

My guess would be the head needs skimming.

Re: Definitely headgasket?

Posted: Sat May 10, 2014 10:57 am

by banner001

CaNsA wrote:My guess would be the head needs skimming.

+1, or at the very least checked for straightness/level, especially as water has gotten in, if its leaked with a new gasket, and the head was installed and torqued correctly in the proper criss-cross pattern its likely that there is enough of a gap for coolant to be forced in to the cylinder. you might wanna get the cylinders checked as well for damage/straightness/level.

Re: Definitely headgasket?

Posted: Wed May 14, 2014 5:54 pm

by Madderz

banner001 wrote:CaNsA wrote:My guess would be the head needs skimming.

+1, or at the very least checked for straightness/level, especially as water has gotten in, if its leaked with a new gasket, and the head was installed and torqued correctly in the proper criss-cross pattern its likely that there is enough of a gap for coolant to be forced in to the cylinder. you might wanna get the cylinders checked as well for damage/straightness/level.

+1 Personally I'd start by checking the head with an engineered straight edge and torch/feeler gauges. Diagonally from each corner, horizontally through all 4 cyclinders/chambers, middle, top and bottom. Then just to be safe i'd go vertically across all 4 cyclinders/chambers. If you can see light or get your smallest feeler gauge through that's probably also where your coolant is getting through.

If that's the case. Get her skimmed.